Product Description

• Moment nut, piercing pressure is constant, keep good electric connection and make no damage to lead.

• Adopted special connecting tablet, apply to joint of Cu (Al) and Cu (Al) or Cu and Al.

• Small electric connecting resistance,connecting resistance less than 2.5 times of the resistance of branch.

• Special insulated case body, resistance to illumination and environmental aging, the insulation strength can up to 12kv.

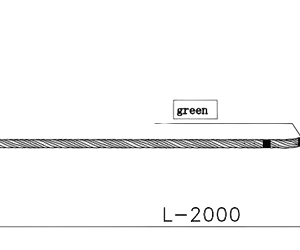

• Arc Surface design, apply to connection with the same (different) diameter, wide connection scope(0.75mm2-400mm2/ td)

Features

Made of hard, corrosion resistant aluminum alloy

Tested according to international and many national standards

Teeth either of pure aluminum or tin-plated aluminum

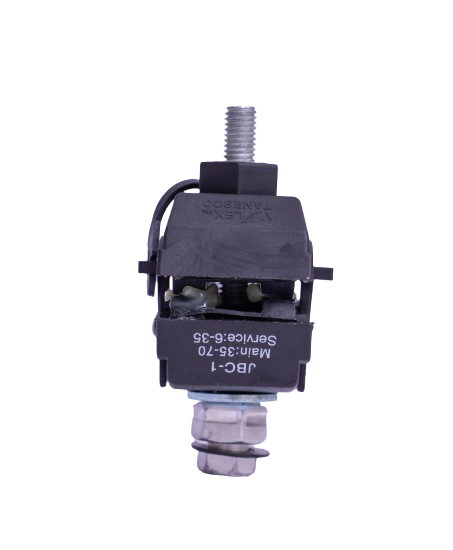

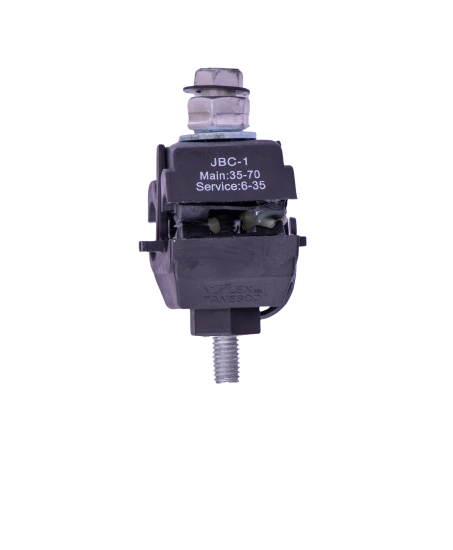

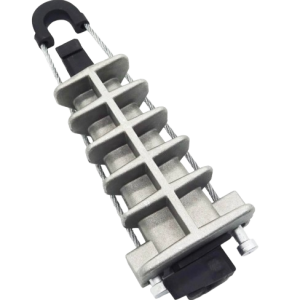

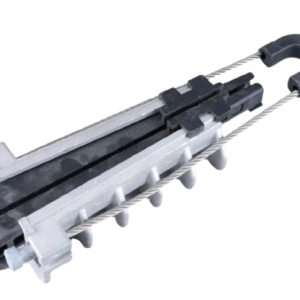

Construction

Component:Material

Body:Tin coated corrosion resistant aluminum alloy

Washer:Conical spring washer

Screw:Hot dip galvanized

Cover:Weather and UV-radiation resistant plastic

Installation:Remove conductor inlet caps according to the connection to be made. Open the upper lid.Unscrew the screw until the conductors can be placed into the connector. Tighten the screw until the shear head breaks. Shut the upper lid.

Installation Insulation Piercing Connector1.Adjust the connector nut to suitable location.

2.Put the branch wire in to the cap sheath fully.

3.Insert the main wire if there are two lays of insulated lay in the main cable, should strip a certain length of the first insulated lay from inserted end.

4.Turn the nut by hand, and fix the connector in suitable location.

5.Screw the nut with the sleeve spanner.

6.Screw the nut continually until the top part is cracked and dropped down.

Reviews

There are no reviews yet.